Valves

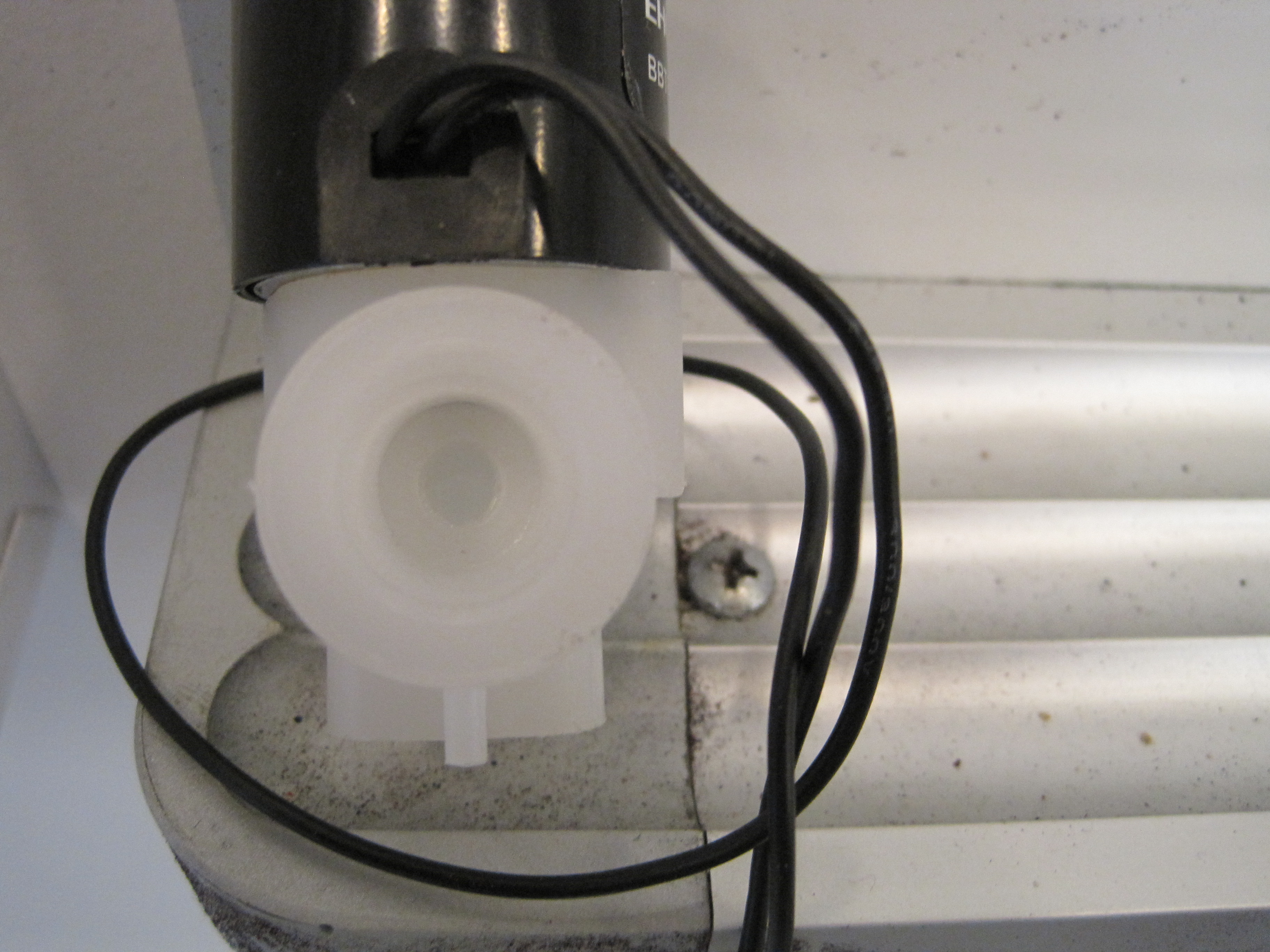

Our original design incorporated three solenoid valves, which were selected because we possessed a few of them already. Unfortunately, while these valves have half inch inlets and exits, the pore through which all the water must travel is approximately 1/16th inch in diameter. This means the water has to move 64 times as fast through the pore as it does everywhere else. Moving water through the valve at a high flow rate requires an enormous pressure drop. As pumps must do work to pressurize the water, less of the power can go to making that water go fast.

As the solenoid valves did not meet the needs of our project, we had to consider other valves. All commercially available, electrically actuated valves capable for our flow rates exceeded our budget. We opted to manufacture our own valves, choosing to build a pinch valve due to simplicity and reliability. The pinch valves that float freely on the outlet tubes. To actuate the valves, a servo turns, compressing latex tubing between its arm and a bolt. This design necessitated that we switch from vinyl tubing to latex tubing, to increase the tubing flexibility. The valves require high torque servos, which are expensive, but which we already owned. Also, the valves consume power while they are closed. While the valves are only closed when spraying, the meager battery life of the boat could be augmented if the valves could be locked closed.